The technologies of the solar thermal

LOW TEMPERATURE SOLAR THERMAL COLLECTORS

The low temperature solar thermal collectors generally used in the solar thermal systems are divided into three types:

| - |

plastic flat-plate collectors, unglazed; |

| - |

flat-plate glazed collectors; |

| - |

vacuum collectors, which are the

most efficient and expensive, proper to the heating integration

of the buildings thanks to the heat diode effect granted by the

vacuum and to their higher efficiency, above all in winter. |

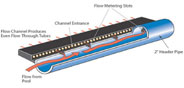

PLASTIC FLAT-PLATE COLLECTORS, UNGLAZED

This first solution is surely the least expensive and it is mainly proper to the use in summer as there is no covering glass and no insulation, which causes great losses with low external temperatures. The water to be heated is passed directly into the solar thermal module; in this way the heat exchanger is avoided and the plant costs decrease. This solution is excellent for heating water in:

- outdoor swimming pools;

- showers on campsites and bathing establishments;

- summer residences.

|

|

|

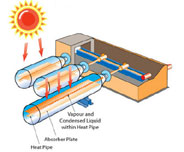

VACUUM COLLECTORS

The vacuum collectors are the most modern, efficient and expensive, in particular proper to the heating integration of the buildings thanks to the heat diode effect granted by the vacuum and to their higher efficiency, above all in winter. Thanks to their innovative characteristics, they have a higher efficiency of 15-20% compared to the flat-plate glazed collectors, but their higher cost suggests their use only on the mountains with rigorous climate or in systems demanding higher water temperatures (passive air-conditioning, buildings heating, ext.). The vacuum collectors grant a good architectonic integration having a tubular shape and small dimensions. In most cases the system is a forced-circulation one, therefore it is similar to the flat-plate glazed collectors installed with the same plant philosophy as far as complexity is concerned. The technology of the vacuum collectors is consolidated and the system doesn’t present particular problems. The main characteristics of the vacuum collectors are the following ones:

|

| - |

good operation also in overcast days and with ambient temperatures below zero; |

| - |

no heat losses; |

| - |

more expensive than the flat-plate glazed collectors; |

| - |

asy installation (easier and easier for natural circulation systems); |

| - |

better architectonic integration (smaller surface with the same performance); |

| - |

good knowledge of this technology. |

|

|

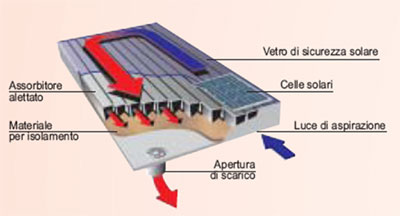

HOT AIR SOLAR COLLECTORS

They are the least spread solar collectors. They are mainly used in the drying systems and only recently they are also considered in the bio-building industry for the production of thermal energy.

They are simpler than the collectors for the hydraulic use, easy to be installed and in some cases they need only forced ventilation systems.

Some companies producing hot air solar collectors have realized modules with an integrated photovoltaic part, which is used to supply a small fan placed in the module itself (an example is the TWINSOLAR hot air module on the right).

|

|

|

HIGH TEMPERATURE SOLAR THERMAL COLLECTORS

High temperature solar thermal collectors are generally used in big plants, which usually use the thermal energy for the production of vapour. This vapour is then carried to turbines connected to generators for the production of electrical energy.

The systems for the production of high temperature are divided into:

| - |

systems with linear parabolic collectors; |

| - |

systems with heliostats and central receiver |

System with linear parabolic collectors |

System with heliostats and central receiver |

SYSTEMS WITH LINEAR PARABOLIC COLLECTORS

The systems with linear parabolic collectors are surely the most known for the production of electrical energy from the thermal energy produced by the sun. In America in the Mojave desert 9 solar thermoelectric systems of this type have been functioning for 20 years for a total electrical power of 350MW.

The installation philosophy of these plants is not very different from the photovoltaic one, there are always modules in series or parallel to reach the power desired.

The high modularity of the system grants a particular easiness for dimensioning the final plant.

Each collector is formed by a particular pipe, around which a mirror reflector of a parabolic form is shaped and it acts like a concentrator. Inside the pipe a fluid carrying heat flows, then it is pumped and reaches the exchanger where it gives thermal energy. The heat produced is transformed into vapour which makes a turbine and an electrical generator function. The average temperature in these systems is about 390°C.

|

|

Kramer Juction plant - California |

|

HELIOSTAT SYSTEMS WITH CENTRAL RECEIVER

In the systems with central receiver the sunlight is collected and concentrated by mirrors called “heliostats” mounted on mechanical systems following the sun during the whole day.

In this way the central receiver located on the top of a tower is struck by the concentration of the solar beams produced by the mirrors put on the ground. Inside the receiver the average temperature reaches 570°C and in this case too vapour is produced to supply an electrical turbogenerator.

There are other types of heliostat systems. Some companies dealing with this sector use circular parabolas with a diameter of 10m, on whose focus gas STIRLING motors are put. They are much simpler than vapour systems and through these motors complete modules of electrical production of small power (electrical 10 KW) can be built.

|

|

Solar Two plant of 10MW - California |

|

|

| |

» The

Technologies

|

|

|

|

|

|